In the non-ferrous industry, the production of aluminum ranks first in the world, and it is also the largest consumption of refractory materials. Aluminum production requires the extraction of industrial alumina from bauxite, which is then used as a raw material to produce aluminum metal. The process of aluminum electrolysis production is by the method of molten salt electrolysis using cryolite alumina. Molten cryolite is the solvent, alumina as the solute, carbonaceous body as the anode, aluminum liquid as the cathode, pass into a strong direct current, at 950 ° C - 970 ° C, in the electrolytic tank on the two poles to carry out the electrochemical reaction, that is, electrolysis.

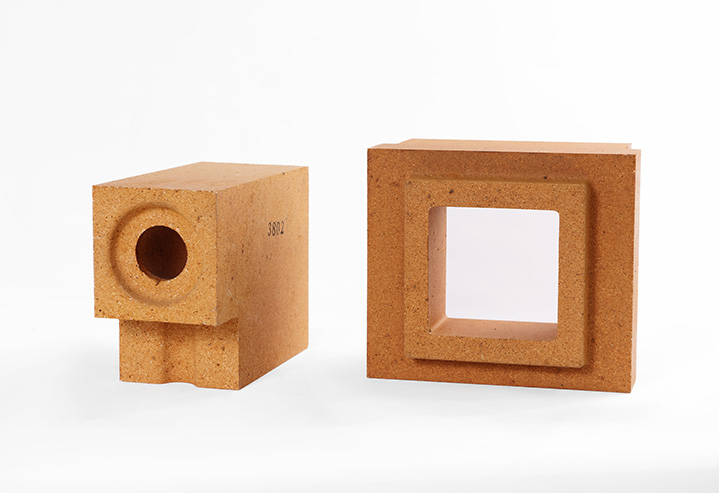

The main thermal equipment for smelting aluminum is a calcining rotary kiln, a carbon roasting furnace, an electrolytic cell, an aluminum melting furnace, etc. Different thermal equipment requires different refractory materials. Common products are: clay bricks, lightweight mullite bricks, low creep clay bricks, high alumina bricks, mullite bricks, corundum mullite bricks, mullite bricks, etc. Laminated castable, non-stick aluminum castable, etc.

| Item | clay brick | Lightweight mullite brick | low creep clay brick | High alumina brick | Mullite Brick | corundum mullite brick | Mullite castable | Non-stick aluminum castable |

| Al2O3;% | ≥42 | ≥42 | ≥42 | ≥55 | ≥70 | ≥85 | ≥65 | ≥80 |

| Fe2O3;% | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 | ≤0.8 | / | / |

| Apparent porosity;% | ≤22 | / | ≤20 | ≤22 | ≤18 | ≤16 | / | / |

| Bulk density;g/cm3 | ≥2.15 | ≤1.0 | ≥2.3 | ≥2.2 | ≥2.55 | ≥2.85 | ≥2.45 | ≥2.8 |

| Cold crushing strength;Mpa | ≥30 | ≥5 | ≥40 | ≥35 | ≥60 | ≥80 | ≥30 | ≥80 |

| Modulus of rupture;Mpa | ≥8 | ≥12 | ||||||

| 0.2MPa refractoriness-under-load/℃ | ≥1400 | / | ≥1450 | ≥1450 | ≥1600 | ≥1650 | / | / |

| 0.2Mpa high temperature creep rate;% | / | / | 1280℃*25h ≤0.8 |

/ | / | / | / | / |

| Permanent linear change on heating;% | 1300℃*2h +0~-0.4 |

1350℃*12h +0.5~-1.5 |

1450℃*2h +0.1~-0.3 |

1450℃*2h +0.1~-0.4 |

1450℃*2h +0.2~-0.2 |

1500℃*2h +0.1~-0.1 |

/ | / |

| Application | Side wall, furnace bottom | Side wall and furnace bottom insulation layer | fire wall | combustion port | aluminum melting furnace | aluminum melting furnace | combustion port | aluminum melting furnace |

Float Kiln

Cement Kiln

Lime kiln

Ladle

Pretreatment of Liquid Iron