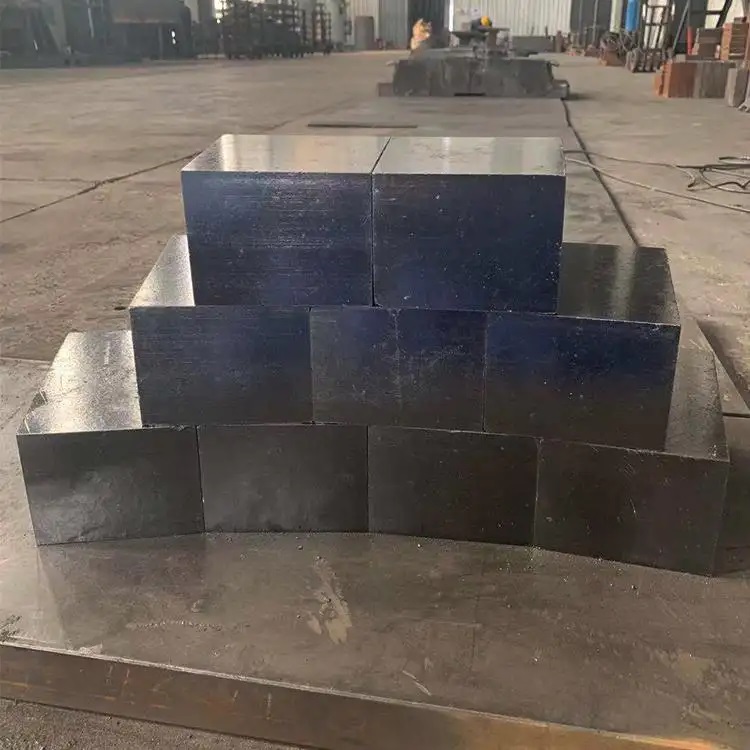

Burned microporous alumina-graphite bricks are made of dense corundum, super-grade bauxite clinker, high-temperature electrically calcined anthracite, graphite, and silicon carbide as the main raw materials. Add the phenolic resin as a binder and adopt the micropore generation process. The bricks are fired in a high-temperature reducing atmosphere after being formed.

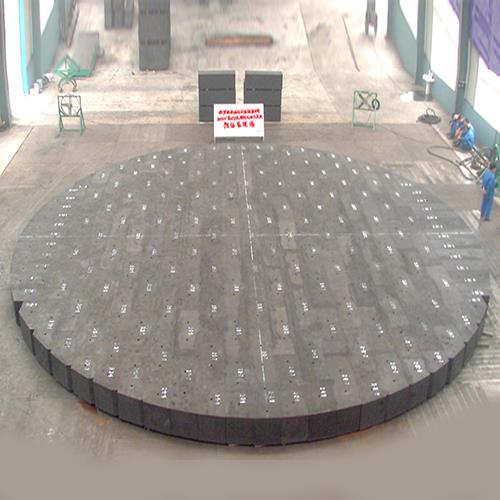

Burned microporous alumina-graphite bricks are suitable for the middle and lower parts of large blast furnaces, furnace waist, furnace belly, furnace hearth and furnace bottom.

Welcome to inquiry us about the price, size, technical data and any information you want to know about Burned microporous alumina-graphite bricks.

Performance Characters:

|

Item/Grade |

WLT-1 |

WLT-2 |

|

|

Al2O3 % |

≥65 |

≥60 |

|

|

C % |

≥11 |

≥11 |

|

|

Apparent porosity; % |

≤16 |

≤17 |

|

|

Bulk density; g/cm3 |

≥2.85 |

≥2.65 |

|

|

Cold crushing strength; Mpa |

≥70 |

≥60 |

|

|

Molten iron corrosion index; % |

≤2 |

≤3 |

|

|

Thermal conductivity (W/(m·K))

|

Room temperature |

≥16 |

≥16 |

|

300℃ |

≥15 |

≥15 |

|

|

600℃ |

≥14 |

≥14 |

|

|

800℃ |

≥13 |

≥13 |

|

|

Alkali-resistance; % |

≤10 |

≤10 |

|

|

<1μm pore volume; % |

≥80 |

≥70 |

|

Al2O3-SiC-C bricks

Alumina-magnesia-carbon bricks