Cement kiln is a commonly used equipment in the cement production process, which is mainly used for calcining raw materials at high temperature, volatilizing the moisture, organic and inorganic impurities in the raw materials, and finally obtaining cement clinker. Cement kiln type has experienced the development of vertical kiln - mechanical vertical kiln - wet rotary kiln - new dry rotary kiln several stages, dry production of cement is currently the most mature and stable cement production process.

New dry-process cement production line mainly consists of preheater, decomposition furnace, rotary kiln, grate cooler, three air ducts are composed of several systems, their respective areas have different working characteristics and use of the environment, new dry-process rotary kiln due to process characteristics caused by alkali, sulfur and other volatile components of the enrichment, the kiln temperature, kiln diameter increased, kiln speed accelerated, the structure of the complexity of the reason, resulting in the refractory material of the chemical attack, high temperature damage, mechanical stress and thermal stress and other comprehensive crushing effect is greater than the traditional kiln. Stress and thermal stress and other comprehensive crushing effect than the traditional kiln is greater, coupled with the current higher environmental protection and energy saving requirements, should be based on the characteristics of the working conditions, each region should be selected from different refractory materials.

The thickness of refractory bricks should be within a reasonable range, its life is not proportional to the thickness, for the expansion coefficient of the refractory bricks, too thick lining due to the temperature difference between the inner and outer layers and the expansion of the amount of the difference is too large, often lead to early damage to the inner layer of the work!

| Kiln diameter (m) | <3.6 | 3.6-4.2 | 4.2-5 | >5 |

| Recommended brick thickness (mm) | 180 | 200 | 220 | 250 |

| Cement rotary kiln refractory configuration | |

| Kiln location | Refractory Configuration |

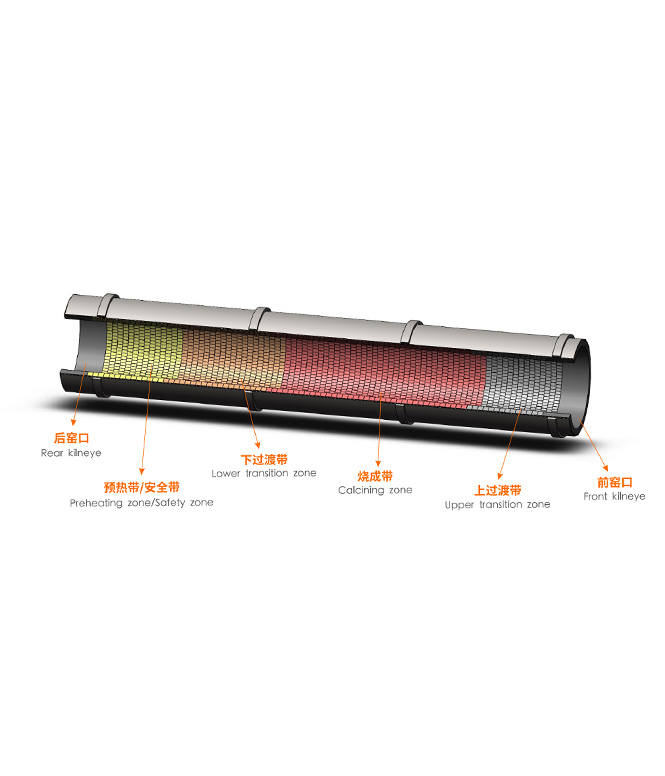

| Rear kilneye | Corundum wear-resistant castables |

| Preheating zone/sadety zone | High aluminum brick |

| Lower transition zone | Silmo Red Brick |

| Calcining zone | Magnesium-aluminum Spinel bricks/ Magnesium-iron Spinel bricks |

| Upper transition zone | Silmo Red Brick |

| Front kilneye | Corundum wear-resistant castables |