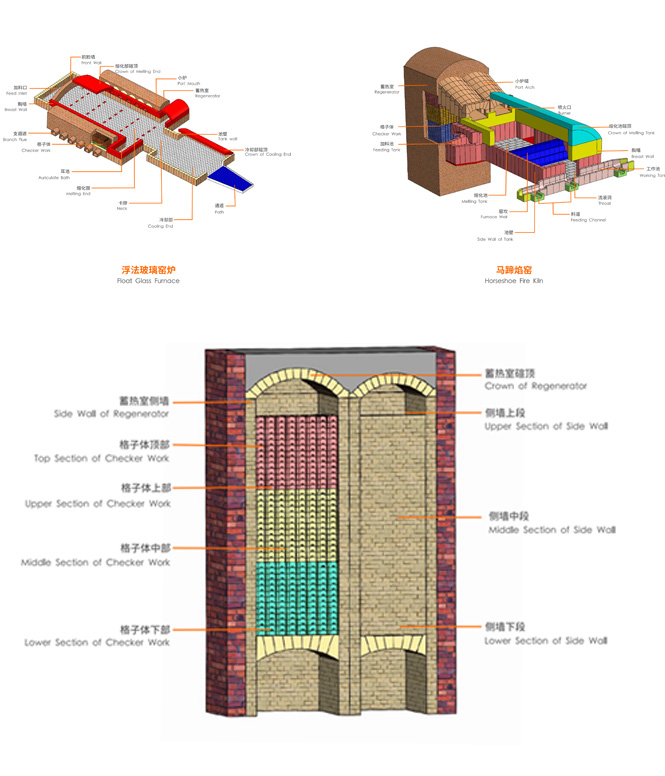

The glass melting kiln is the heart of the glass factory, the key equipment for "turning sand into gold" and an important part of fuel consumption. For float glass kilns, fuel costs account for about 40% of the cost of glass production. Therefore, to improve the utilization efficiency of the kiln, the correct use of the glass kiln and key parts of the maintenance, is to extend the service life of the kiln, improve the economic efficiency of the fundamental.

Glass melting kiln is the most critical is the selection and configuration of its refractory materials, because the refractory materials for glass kiln is different from the iron and steel industry, common mostly for the fused refractory materials, but there are also supporting clay brick, high alumina bricks, silica bricks, silica wire bricks, sintered mullite bricks, sintered zirconia mullite bricks, sintered AZS, and so on.