product introduction:

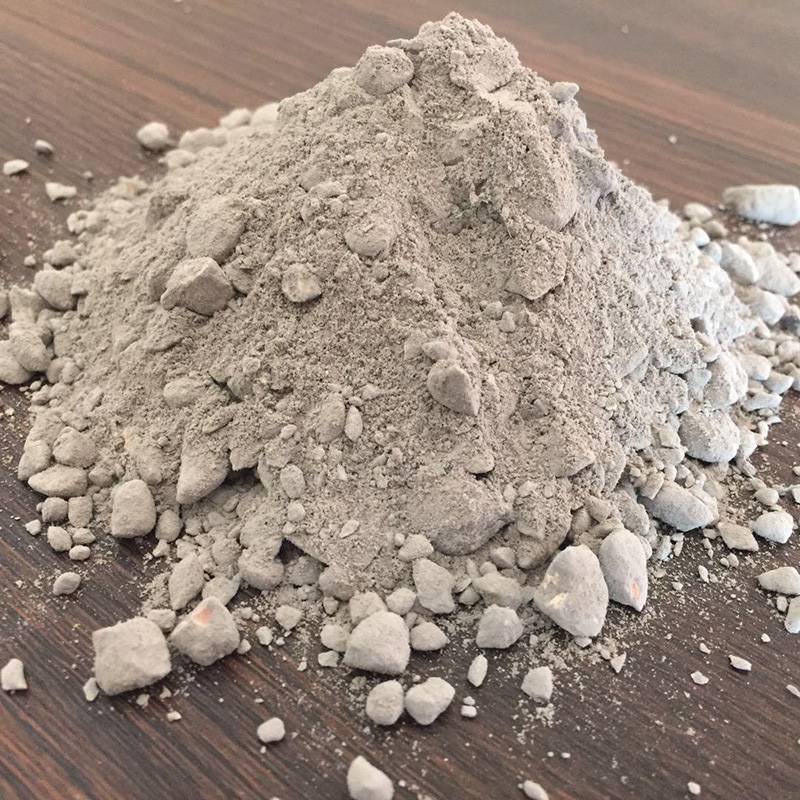

High alumina castable is a kind of unshaped refractory material, which is made of refractory aggregate, refractory powder, binder and other additives. It is unshaped, has high fluidity, can be poured and vibrated into shape, can be used directly, or can be used after adding appropriate amount of water or other liquids. It is a new type of refractory material that does not require calcination.

Product application:

High alumina castable is commonly used in various high-temperature industrial kiln linings such as metallurgical high-temperature kilns, electric boilers, non-ferrous smelting heat treatment furnaces and induction furnaces.

Welcome to contact us for our high alumina refractory castables and any information you want to know.

High alumina wear-resistant castable is characterized by slow hydration rate, high strength and high refractoriness. High aluminum wear-resistant castable has the characteristics of anti-penetration, anti-erosion, anti-impact, anti-wear and good mechanical properties.

Performance Characters:

|

Item/Grade |

GLJ-50 |

GLJ-60 |

GLJ-65 |

GLJ-70 |

GLJ-80 |

|

Al2O3; % |

≥50 |

≥60 |

≥65 |

≥70 |

≥80 |

|

Bulk density; g/cm3 |

≥2.20 |

≥2.30 |

≥2.35 |

≥2.40 |

≥2.60 |

|

Cold crushing strength; Mpa |

110℃×24h ≥25 1200℃×3h ≥45 |

110℃×24h ≥30 1300℃×3h ≥50 |

110℃×24h ≥35 1300℃×3h ≥55 |

110℃×24h ≥40 1400℃×3h ≥70 |

110℃×24h ≥45 1500℃×3h ≥80 |

|

Modulus of rupture; Mpa; |

110℃×24h ≥4 1200℃×3h ≥6 |

110℃×24h ≥5 1200℃×3h ≥8 |

110℃×24h ≥6 1300℃×3h ≥10 |

110℃×24h ≥8 1400℃×3h ≥10 |

110℃×24h ≥8 1500℃×3h ≥12 |

|

Permanent Linear Change On Reheating; % |

1200℃×3h ±0.8 |

1300℃×3h ±0.8 |

1300℃×3h ±0.8 |

1400℃×3h ±0.8 |

1500℃×3h ±0.8 |

|

Curing at room temperature not less than 72h |

|||||