With the development modern blast furnaces with large-scale, high air temperature, and other smelting technologies, the air supply temperature of hot air blast stove is gradually increasing, which has put forward higher requirements for hot blast piping systems that are exposed to high pressure, high temperature, and temperature change. At the same time, the refractory lining of the hot air piping system must also improve its performance. Currently, most of the hot air piping systems of many steel companies use andalusite or low-creep high-alumina bricks for lining. This is mainly to ensure that the materials High-temperature creep performance and thermal shock resistance, then, in order to reduce material costs and installation costs, high-strength composite ceramic wear-resistant mass have replaced some composite bricks in the hot blast stove piping system, which gets obvious success:

1. Physical and chemical performance indicators of high-strength composite ceramic wear-resistant materials

Performance features:

· High strength and good wear resistance;

· Low linearchangesl;

· Good thermal shock stability;

· Good overall performance;

· Good thermal insulation performance;

2. Replace three-bifurcationcomposite bricks

Usually three-bifurcation composite bricks are given an overall structural design proposal by the designing institutes, and refractory manufacturers decompose them into single bricks according to the outer dimensions and then produce and assemble them. Compared with the early standard brick processing and masonry, the stability has greatly improved. However, the requirements of the material, blockdivision and masonry construction of composite brick are still harsh in the harsh working conditions.

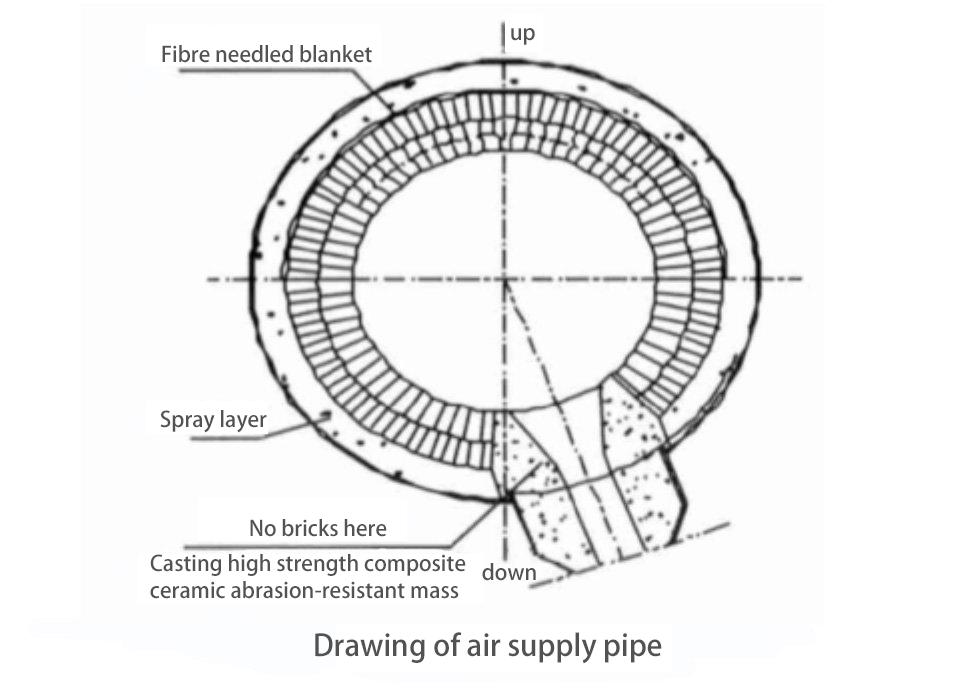

With the advancement and maturity of refractory castable technology, the materials and material properties can also meet the requirements of the modern hot air blast stove environment. Compared with the combined brick construction, the construction of the three-bifurcation pouring construction becomes simple and easy, and the structural integrity is good, no joints, and the possibility of falling bricks and channeling wind in the upper part of the pipeline is avoded.

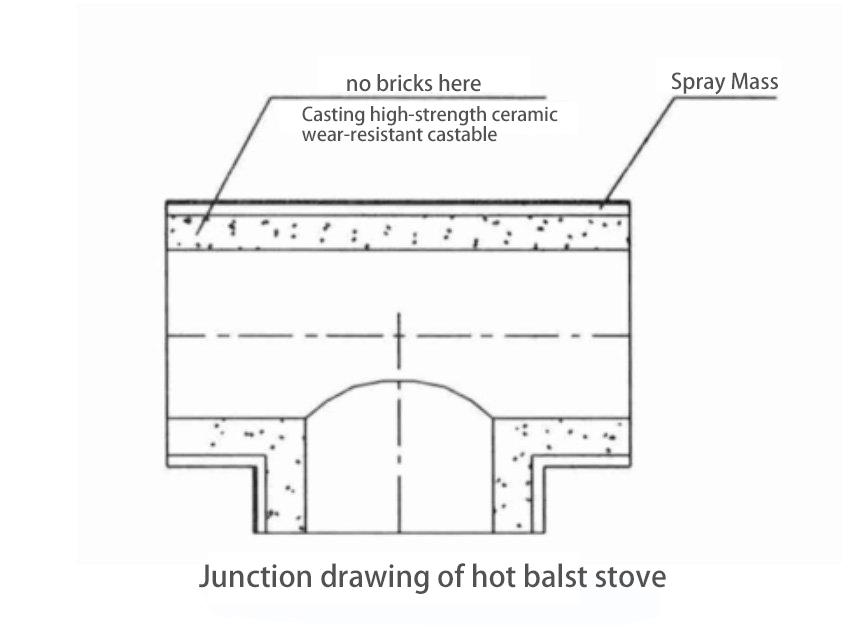

3. Replace the composite bricks at hot air branch pipes, air supply elbows and enclosure pipes

Pouring method can can reduce the difficulty of construction, speed up the construction progress, and ensure the overall stability of the pipeline interface.

4. Replacement proposal forhot air blast stove pipeline maintenance

Common hot air blast stove pipeline maintenance needs to shut down the furnace and make composite bricks according to the damaged parts. This scheme has a long order cycle, difficult construction, and affects the normal production demand of blast furnace. The pouring construction method can speed up maintenance and reduce the difficulty of construction, the furnace shutdown overhaul can speed up the resumption of production time, and a small amount of repair can be temporarily shut down for hot maintenance, which can maintain the normal production of the blast furnace.