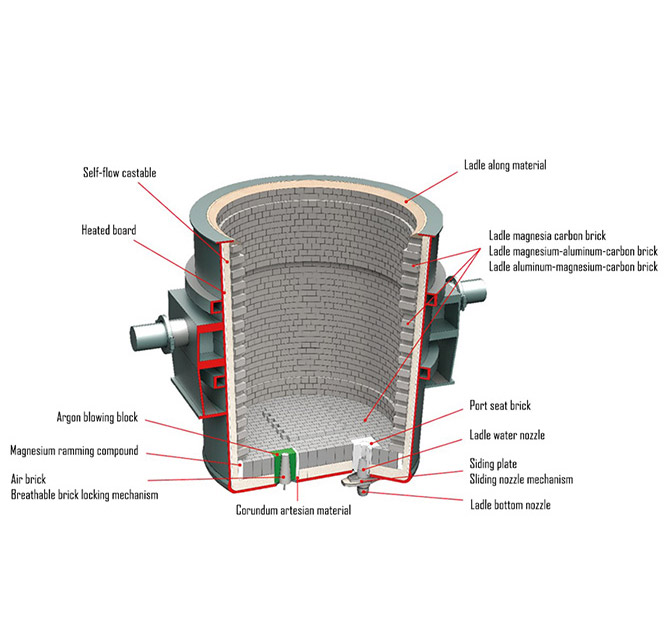

The ladle is responsible for the dual tasks of carrying molten steel and refining outside the furnace. The temperature of the molten steel in the ladle ranges from about 1550 to 1620°C, and the ladle must withstand the impact of severe cold and heat during service. Since the use conditions of the refining ladle are extremely harsh, the arc erosion of the slag line and ladle wall is very serious, resulting in premature damage to the refractory material and becoming the main reason that restricts its service life. Therefore, the requirements for ladle brick lining are higher than those for molten iron ladle brick lining.

In the process of using ladle refractory, the slag is easy to penetrate from the hot surface to the deep inside, so that the porosity near the working face is significantly reduced and densified, and a very thick metamorphic layer is formed. When the temperature changes dramatically, cracks parallel to the working face will occur at the junction between the metamorphic layer and the original brick layer, resulting in spalling and damage.

To reduce the spalling, the method is to reduce the depth of slag infiltration, MARSREF suggested that the following aspects: