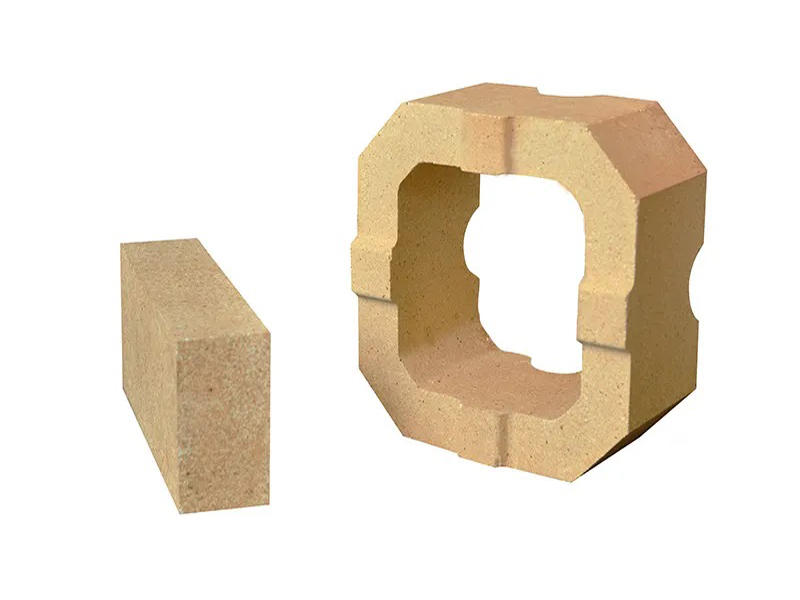

MARSREF is a supplier of Low porosity refractory brick. The porosity of clay bricks is generally 24-26%, while low porosity clay bricks are mostly used between 12-17%, and there are also less than 10% porosity. The low porosity of this bricks is mainly adjusted by coke gems. After adding coke gems, the performance of low porosity clay bricks is improved, and the density, strength, and erosion resistance are improved. Low porosity clay bricks have high sintering temperatures, large changes in raw material matrix, and further improved erosion resistance, thermal shock resistance, and the strength.

Scope of application: Widely used in metallurgy and building materials, petrochemical industry, ceramics and glass, hot air blast furnace, glass furnace regenerator, etc.

Welcome to inquiry us about the price, size, technical data, and any information you want to know about Low porosity refractory brick.

Performance Characters:

|

Item/Grade |

DN-11 |

DN-14 |

DN-17 |

|

Al2O3 % |

≥47 |

≥45 |

≥42 |

|

Fe2O3 % |

≤1.2 |

≤1.5 |

≤1.8 |

|

Apparent porosity; % |

≤11 |

≤14 |

≤17 |

|

Bulk density; g/cm3 |

≥2.4 |

≥2.35 |

≥2.25 |

|

cold crushing strength; Mpa |

≥80 |

≥65 |

≥50 |

|

Refractoriness under load, ℃ 0.2MPa, |

≥1520 |

≥1470 |

≥1430 |

|

Reheating Linear Change % |

1500℃×2h -0.2~0.1 |

1400℃×2h -0.2~0.1 |

1400℃×2h -0.2~0.1 |

Low creep fireclay refractory brick

Dense fireclay brick

Common Clay Brick

Low porosity refractory brick