There are two main types of iron pretreatment system: open iron tank and torpedo iron tank (referred to as torpedo car, mixed-iron car), iron tank is the traditional equipment for transporting iron, the use of more common, mixed-iron car capacity is generally 100 to 150t, large mixed-iron car can hold 400 to 600t of iron. In certain protective conditions, mixed iron car can be sent to the iron tens of kilometers away from the place, and the temperature of the iron is reduced less, can save energy.

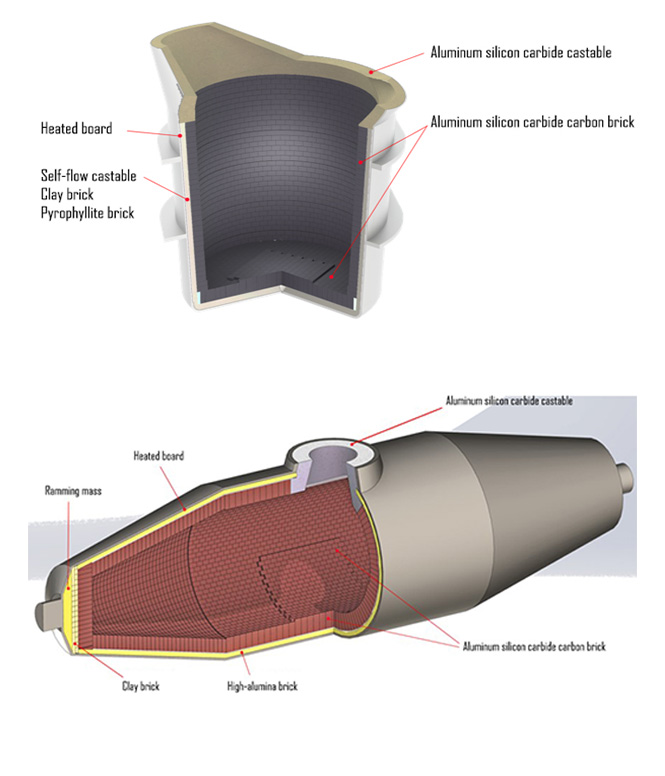

According to the shape is also known as iron water tank, iron package, iron barrels, mixed iron car, torpedo tank, designed for steelmaking supporting the design, so according to the capacity to be divided, there are many types of furnace, but the shape is similar, relative to the majority of industrial furnaces in the steel plant, the iron water tank structure is relatively simple, the lining material requirements are not high, generally using high alumina, aluminum carbon or aluminum silicon carbide refractory materials, the construction sequence: the bottom of the packet of permanent layer -Package wall permanent layer -Package bottom working layer -Package wall working layer.

Iron pretreatment system refractories should have the performance: