Casting is the process of getting the desired products by pouring a molten metal liquid into a casting mold, and then cooled and solidified. Casting is a common used manufacturing method, with low manufacturing costs and great process flexibility to obtain complex shaped and large castings.

Due to today's casting quality, casting accuracy, casting costs and casting automation and other requirements, casting technology to precision, large-scale, high-quality, automation and clean direction, and casting refractory materials used also need to meet the needs of modern production. There are three commonly used products: clay bricks, high alumina bricks and mullite bricks.

| Item | Clay brick | High alumina brick | Mullite Brick |

| Al2O3;% | ≥40 | ≥50 | ≥60 |

| Fe2O3;% | ≤2.0 | ≤2.0 | ≤1.8 |

| Refractoriness;℃ | ≥1650 | ≥1700 | ≥1750 |

| Apparent porosity;% | ≤28 | ≤26 | ≤26 |

| Cold crushing strength;Mpa | ≥35 | ≥45 | ≥35 |

| Permanent linear Change on heating;% | 1300℃×2h 0.2~0 |

1350℃×2h -0.4~0 |

1400℃×2h -0.1~+0.4 |

| Application | Flow steel brick series | Flow steel brick series | Flow steel brick series |

Refractory materials for Blast furnace

Coking

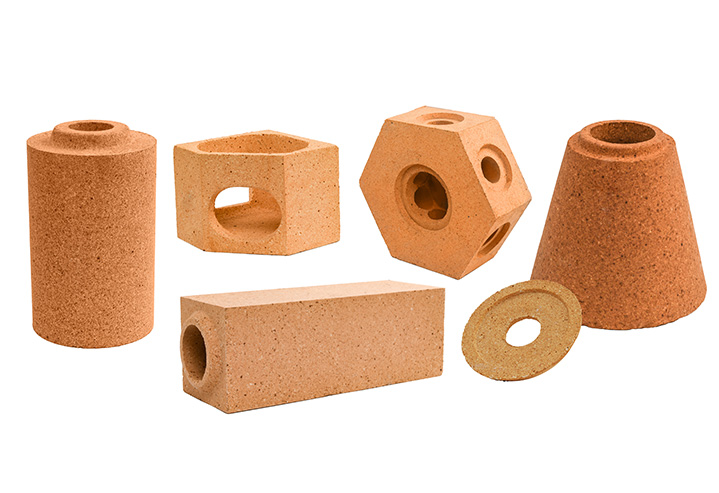

Refractory materials for casting

Hot blast stove

Pretreatment of Liquid Iron