In order to meet the personalized needs of customers, MARSREF has complete testing equipment and professional testing personnel, and has passed ISO9001 quality management system certification, providing sufficient guarantee for product quality.

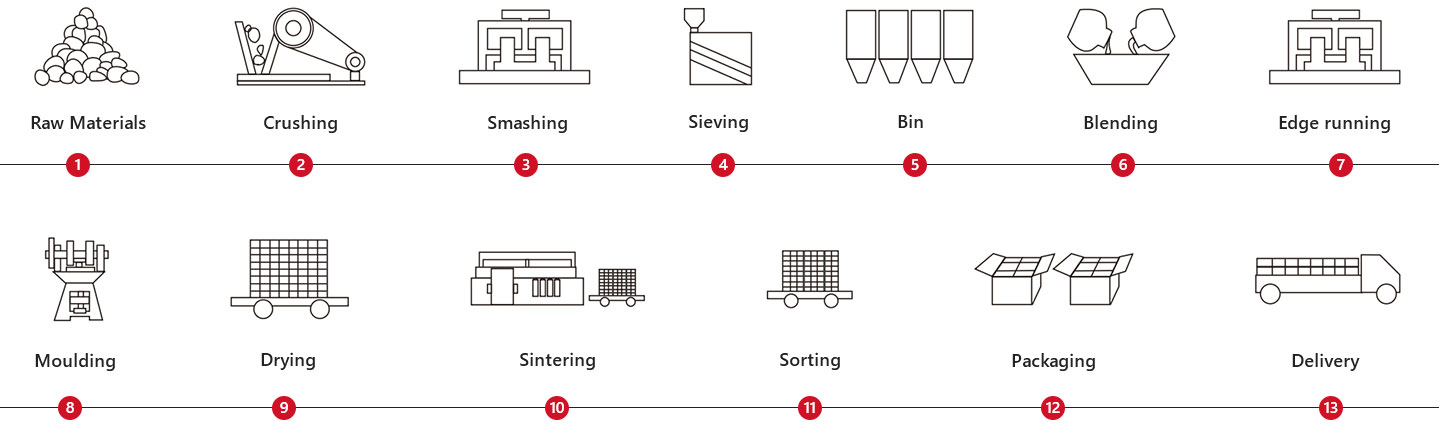

Analyze the chemical composition of each batch of purchased raw materials to ensure that they meet the requirements of the product process, and enter different warehouses according to different materials to avoid mixed grades of materials;

Inspect the appearance size, distortion, cracks and other defects of the bricks, record the inspection results of the semi-finished products, sign for acceptance if they are qualified, and scrap them for grinding if they are not qualified;

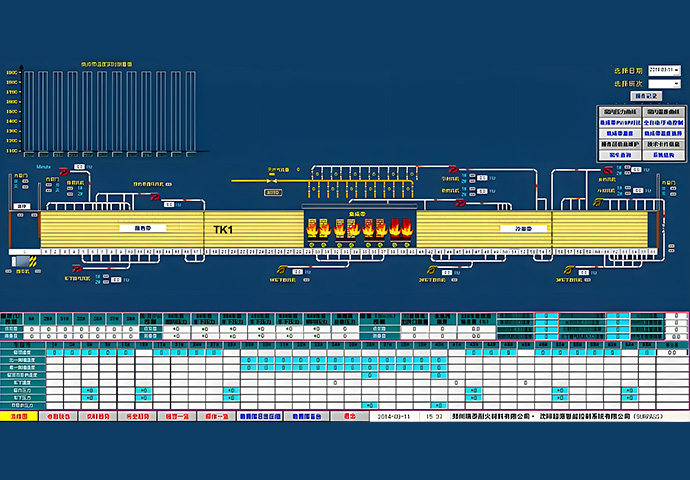

The product’s sintering temperature and holding time are strictly controlled in accordance with the product process instructions, and the sintering temperature curve is measured and recorded;

Inspect the products according to the size requirements of the product drawings, and also check for appearance defects such as distortion, cracks, missing corners, etc., mark and classify qualified products; then conduct sampling and testing according to different materials, and issue Test Report;

Pack products according to customer requirements to ensure that they meet customer packaging standards and meet railway and sea transportation requirements to ensure that products are delivered to customers without damage.

In order to provide customers with more professional and detailed services, MRASREF can undertake the production process supervision services of refractory materials and help customers who have placed production orders in China to inspect and accept related refractory materials products, allowing customers to clearly understand the production of products. schedule and product quality. Because we have rich refractory knowledge and a professional technical team, we can help customers accept products from other factories, which can involve ISO, ASTM, EN, DIN and other standards, and provide professional production process supervision services for various fields of high-temperature industry.