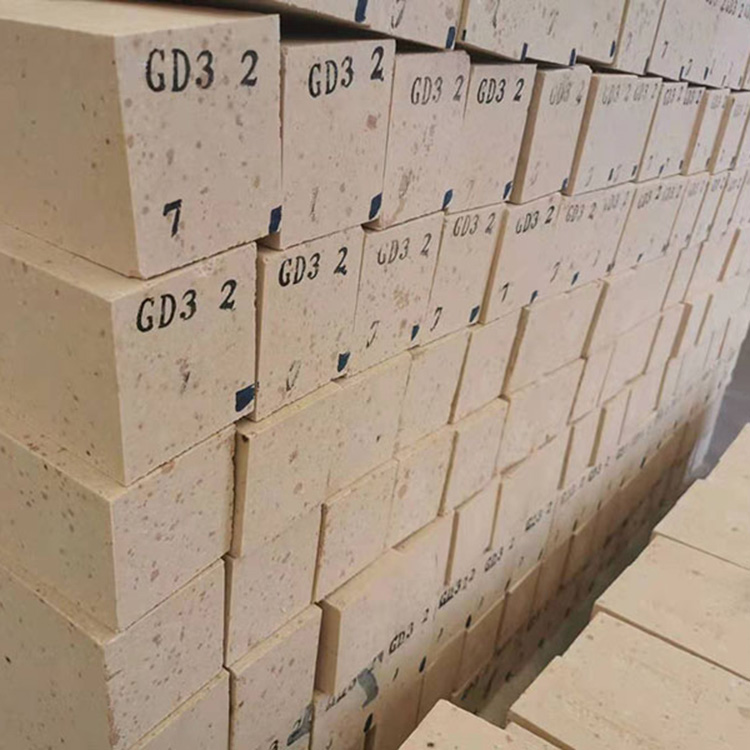

MARSREF is a supplier of silica refractory bricks. this brick is made of quartz raw materials with a SiO2 content of more than 94%. They are resistant to acid slag erosion and have under load temperature of 1620-1670℃. They are not easily deformed when used for a long time in a high temperature environment.

Silica refractory bricks are widely used in the steel industry like coke ovens and hot blast furnaces, and glass kilns in the glass industry, as well as carbon furnaces in the aluminum industry, etc.

Welcome to inquiry us about the price, size, technical data and any information you want to know about Silica refractory bricks.

Performance Characters:

|

Item/Grade |

GZ-94 |

BG-96 |

JG-94 |

RG-95 |

|

SiO2 % |

≥94 |

≥96 |

≥94 |

≥95 |

|

Fe2O3 % |

≤1.4 |

≤0.8 |

≤1.5 |

≤1.0 |

|

Apparent porosity; % |

≤24 |

≤21 |

≤22 |

≤22 |

|

True density; g/cm3 |

≥2.35 |

≥2.34 |

≥2.34 |

≥2.34 |

|

cold crushing strength; Mpa |

≥30 |

≥30 |

≥35 |

≥35 |

|

0.2Mpa Refractor iness Under Load ℃ |

≥1650 |

≥1680 |

≥1650 |

≥1650 |

|

Permanent Linear Change On Reheating % |

- |

1450℃X2h +0.2 |

1450℃X2h +0.2 |

- |

|

Thermal expansion(1000℃)% |

- |

- |

≤1.30 |

≤1.28 |

|

Furnace type used |

Ordinary silica brick |

Glass kiln silica brick |

Coke oven silica brick |

Hot blast stove silica brick |

Silicon Carbide Brick